Features of mattresses with independent springs

Adequate sleep determines a person's quality of life and energy level during the day. According to scientific research, the type of mattress a person uses affects the quality of sleep. To eliminate problems that hinder sleep, such as hesitation when moving, metal sounds and protruding springs, the experts have developed mattresses with an independent spring block, which provide reliable support without additional inconvenience.

Advantages and disadvantages

Pocket-type mattresses have a number of important advantages over conventional products with a standard block of dependent springs.

Advantages of sleeping products with a block of independent springs:

- no squeak, since each element is isolated;

- Suitable for overweight customers as the point-type compression provides a hammock effect;

- load evenly distributed over the surface, which means that the spine is in a natural position;

- provide a relaxing effect;

- designed for increased surface loads from 150 to 200 kilograms;

- suitable for long-term use thanks to the high quality coating and filling.

Disadvantages:

- the possibility of acquiring a fake is not excluded, therefore, the product should be checked before purchasing;

- overpriced, although there are products with airbags of different price categories on the market (if there are indications for the use of this particular type, the high cost will pay off within a few months);

- low wear resistance in case of incorrect use of products.

How are they different from other species?

To highlight the key benefits of BNP products, compare them with other types of products. Mattresses can be divided into several categories, depending on the type of spring element and its presence or absence:

- products with BNP - a block of independent spring elements (TFK);

- goods with dependent springs;

- springless options (from coconut coir, latex, polyurethane foam and other types of fillers).

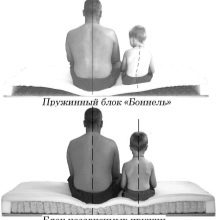

A mattress with an airbag, unlike springless mattresses, contains spring elements. And unlike the standard spring type, the five-turn parts in mattresses with airbags are isolated from each other, which ensures that there is no squeak when moving. In early models with an independent spring block, deformation of individual parts occurred under uneven pressure in different places of the product. Thanks to modern developments, this disadvantage has been eliminated by adjusting the rigidity and adding additional details.

Mattresses with an independent spring block consist of standard five-coil springs, each of which is placed in a special "glass" made of fabric. The springs with a fabric cover can be combined into ribbons of different sizes. On one side, the springs are connected to each other, while the load is not transferred to adjacent elements. The structure of the mattresses resembles the Bonnel type, complemented by a Euro frame around the perimeter and upholstery fabric.

The main advantages of this design include high orthopedic qualities, no ripple and squeak. Products can withstand a high load of up to 150 kg during the entire declared service life. Compared to standard spring mattresses products with BNP are expensive, but the price is offset by high performance and orthopedic properties.

Tip: You can check the mattress for the presence of independent springs by pressing on it and observing the vibrations on the surface.In the absence of the "wave" effect, the mattress meets the standards.

Species overview

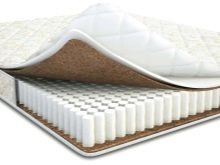

Today there are many varieties of mattresses with independent springs, depending on the purpose, design, degree of rigidity, types of fillers and sizes. For the manufacture of orthopedic sleeping mattresses, the following fillers are used:

- natural latex;

- coconut coir;

- coir cactus;

- woolen or cotton felt;

- horsehair;

- camel or sheep wool;

- regular cotton;

- artificial latex;

- porous polyurethane foam;

- memorial forms.

By design

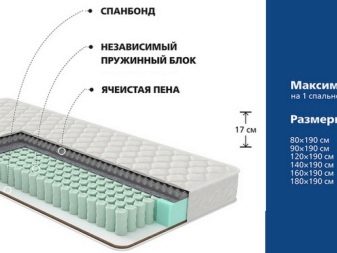

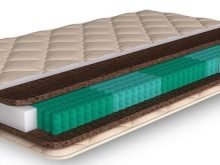

Orthopedic products with an independent spring block are a complex structure, each element of which carries a certain functional load. The construction of the mattress consists of several elements:

- outer cover made of durable fabrics;

- side walls made of dense types of foam, which serve as a frame;

- spring block with independent elements;

- internal fillers made of natural or synthetic materials, which regulate the degree of rigidity of the product.

In different embodiments, different combined types or one suitable component can be used.

In mattresses with an independent spring block, the metal elements are insulated with a fabric cover to avoid the “wave” effect and friction of the springs. Depending on the type of construction, it is customary to distinguish the following types of blocks with independent springs.

- TFK springs. The standard product includes 256 springs per square meter.

- Multipack consists of 500 small springs that provide additional support and an orthopedic effect. The multi-package is ideal for people with a large build.

- Micropackage contains from 1000 small springs per square meter. The products were developed for obese people and have a pronounced orthopedic effect.

- "Duet" - a block consisting of large springs, inside of which there are additional small elements. This variety is intended for couples with a difference in the weight of partners.

- Zone spring block helps to distribute the load depending on the parts of the body.

By the level of orthopedic effect

The effect of the mattress on the human skeleton is determined by the degree of rigidity of the product.

Depending on the degree of rigidity, the following types of goods are distinguished:

- softsuitable for adults with low weight and the elderly;

- medium hardness - standard products intended for healthy adults;

- tough - great for children.

To create an additional effect of rigidity, manufacturers use various materials:

- coira - made from the inner part of the brown shade of coconut;

- sisal - Agave leaves are used as raw materials;

- thermal felt - dense polyester material with additives from natural ingredients;

- bicocos - a combination of coir and a synthetic component with a low degree of elasticity.

Fillers provide an average degree of hardness:

- polyurethane foam - conventional polyurethane foam with increased density;

- holofiber - a set of polyester, glued together fibers with a vertical arrangement;

- struttofiber - a filler with natural and cellulose fibers, which has increased softness and hygroscopicity.

From soft fillers can be distinguished:

- memory foam - a filler capable of returning to its initial shape is considered a type of foam rubber;

- artificial latex - one of the varieties of polyurethane foam, similar in properties to natural latex material;

- natural latex - foam material with a fine-mesh structure, which has a high degree of softness and elasticity.

Dimensions and weight

Sleeping and orthopedic stores offer a wide range of standard and custom sizes. The most common are (in cm):

- 160x200 - standard size double mattress;

- 140x200 - double option for adults;

- 180x200 - widened version of a double product;

- 90x200 - single, increased in width mattress, perfect for a sofa;

- 80 to 190 - standard single piece;

- 120x200 - one and a half bed mattress;

- 80x200 - standard size for a single bed option;

- 90x190 - single mattress with emphasis on the width of the product.

A high orthopedic double mattress weighs 30 kg. The product with the maximum thickness weighs about 50 kg.

The weight of the mattress depends on several parameters.

- Product thickness - the thicker the mattress, the more it weighs, although there are exceptions. It is best to check the weight of the product with the seller.

- Filler - artificial materials weigh less than natural materials.

- Hardness degrees - the stiffer the product, the higher its weight. Artificial litters contain a lot of air due to their foam structure, so they are lighter.

Top brands

Technologies for the production of orthopedic sleep products are improving, as a result of which the list of the best manufacturers is changing. According to last year's data, the following companies became the best.

- "Ormatek" Is a large manufacturer of spring mattresses for adults, adolescents and children, with a 20% market share. The company works with all types of mattresses, but focuses on products with BNP.

- Vegas Is a Belarusian manufacturer that boasts the use of imported raw materials and modern equipment. The brand produces products of different stiffness and presence of springs. Every year the company replenishes its proven collections with new developments that make sleep comfortable and pleasant.

- "Ascona" - is a leader in Europe, uses only advanced technologies, has numerous quality certificates, offers products in different price categories.

- "Consul" - a holding company with an 80-year history with a minimum mark-up on products. The industry leader can afford to set prices on his own, although some customers note the inadequate quality of the material used to sew covers.

- Lonax Is a new company offering a wide range of products in standard and non-standard shapes.

- "Virtuoso" - a company that uses technologies from different countries, offers customers a wide price range of mattresses and an impressive variety of models.

- "MaterLux" Is an Italian company created immediately after the Second World War. Constantly updating the assortment and improving the products.

Nuances of choice

Algorithm for choosing a quality mattress.

- Choose the desired degree of rigidity of the product, depending on the age and the presence or absence of orthopedic problems. For diseases of the spine, hard mattresses are suitable.

- Navigate by the weight of users.

- Decide on the weight and height of the product. If you are overweight, it is important to choose a high mattress. Average thickness is suitable for people with normal body weight. Thin people can save on the height of the product. The height of products with independent springs for adults varies from 18 to 19 cm.

- Select type and size of independent springs.

- Choose a suitable type of filler. For less rigid products, use polyurethane foam, for medium-hard products - natural latex or coconut coir, for rigid products - latex coconut fiber.

When choosing one of the types of mattress, it is important to remember that high cost does not guarantee high quality of the product... You can choose which of the mattresses is better based on the expected load on the product, back health and purpose. For example, as an extra bed, you can use a model with a minimum height, which can be quickly rolled up and put into the pantry.

For the treatment of orthopedic diseases, you should choose types of products of high rigidity.For a comfortable sleep, a mattress with an independent spring block from a well-known manufacturer is ideal for an adult, which will provide the necessary fixation of the spine and will last a long time.